We are Specializing in producing Feed Processing Machinery for 15+ year since 2009.

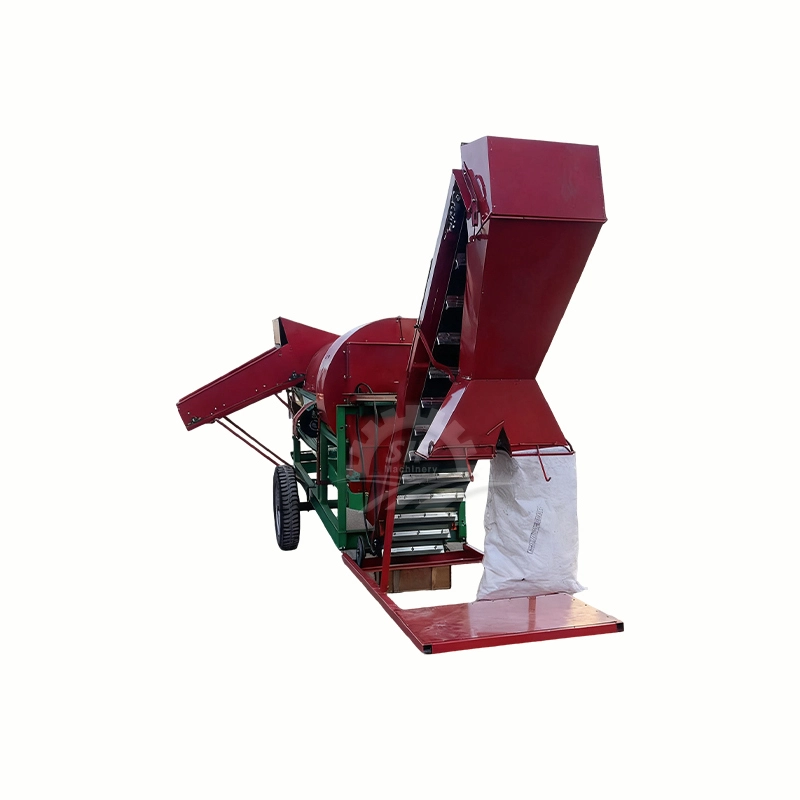

SPN8000 Commercial Peanut Picker Machine - Wet & Dry Tractor-Pulled, 98% Picking Rate, Low Breakage for Farm Business

Product Information

The SPN8000 Commercial Peanut Picker Machine is the ultimate solution for large-scale, high-performance peanut picking for farm businesses. It is designed specifically for commercial farm use and works seamlessly with both wet fresh peanuts and dry peanuts, eliminating the need to switch equipment. This tractor-pulled machine features a 98% picking rate and only 0.2% breakage rate, ensuring maximum crop retention and quality. A built-in fan blows away dirt and debris, producing clean, market-ready peanuts. The machine is lightweight yet sturdy, moving freely in fields while supporting automatic feeding and bagging. It handles 4000-5500kg of peanuts per hour, making it perfect for commercial farms, agricultural cooperatives, and farm equipment dealers. It takes the hassle out of commercial peanut harvesting and boosts productivity for farm businesses.

Product display

Product parameters

|

Product Name |

SPN8000 Peanut Picker Machine |

|

Model |

SPN-8000 |

|

Production Capacity |

4000-5000kg/h |

|

Voltage(if electric) |

380V/Customized |

|

Matched Power |

- Electric Motor: 22KW |

|

Main Machine Weight |

750kg |

|

Overall Dimension (L*W*H) |

6175*1580*2355mm |

|

Threshing Rate |

98.00% |

|

Machine Raw Material |

High Quatlity Steel |

|

Applicable Raw Materials |

Dry or Wet Peanut/groundnut |

|

Usage |

Separate Peanut or Groundnut From Their Straws |

Key Features

● Wet & Dry Dual-Use Versatility: Handles both high-moisture wet peanuts (stem moisture ≥40%) and low-moisture dry peanuts (stem moisture ≤15%) without equipment changes. Adjust roller speed (400-600r/min) and concave plate gap (10-15mm) for optimal results—wider gaps and lower speed prevent breakage for wet crops, while narrower gaps and higher speed boost efficiency for dry ones.

● Multi-Power Compatibility: Flexibly connects to tractor PTO via universal joint, or operates independently with a 22KW motor or ≥28HP diesel engine. Ideal for farms with different power setups, whether you need mobility for field work or fixed-site operation.

Key Advantages

● Time & Labor Saving: On-the-go design lets you harvest while the tractor moves—no stopping to reposition. Automatic bagging collects cleaned peanuts directly into bags, eliminating manual transfer. The vibration sieve and ventilator system removes soil, leaves, and debris in one step, delivering ready-to-store peanuts.

● Durable & Low-Maintenance: Constructed with thickened steel and a reinforced gearbox for high-intensity continuous use. Fully sealed chain wheels and double bearings reduce wear, while corrosion-resistant components extend service life to 5-8 years. Routine maintenance only requires bolt checks, belt tension adjustments, and gearbox lubrication every 50 working hours.

● Wide Application: Suitable for all soil types, flat and ridged peanut fields. Perfect for large-scale farms (≥30 mu/5 acres) and commercial growers, with a low loss rate that maximizes crop yield.

Working Process

● Power Activation: Connect to your chosen power source (tractor/motor/diesel) to drive the gearbox and belt system, powering the picking roller and cleaning components.

● Feeding & Picking: As the tractor moves, feed peanut plants into the hopper. The high-speed rotating rubber-coated roller gently beats stems to separate peanuts without damaging the fruit.

● Cleaning: Separated peanuts fall through the concave plate onto a vibration sieve. The sieve and ventilator work together to remove soil, small leaves, and light debris, ensuring ≤2% impurity rate.

● Auto Bagging: Clean peanuts are conveyed to the bagging outlet for direct collection. Separated peanut vines are discharged from a dedicated outlet, suitable for recycling as forage.

Product application

FAQ

Contact: Ella

Tel: +86 19337183882

E-mail: sif@sifmachinery.com

Address: Gaocun,Guang Wu Road, XingYang, Zhengzhou, HeNan, China