We are Specializing in producing Feed Processing Machinery for 15+ year since 2009.

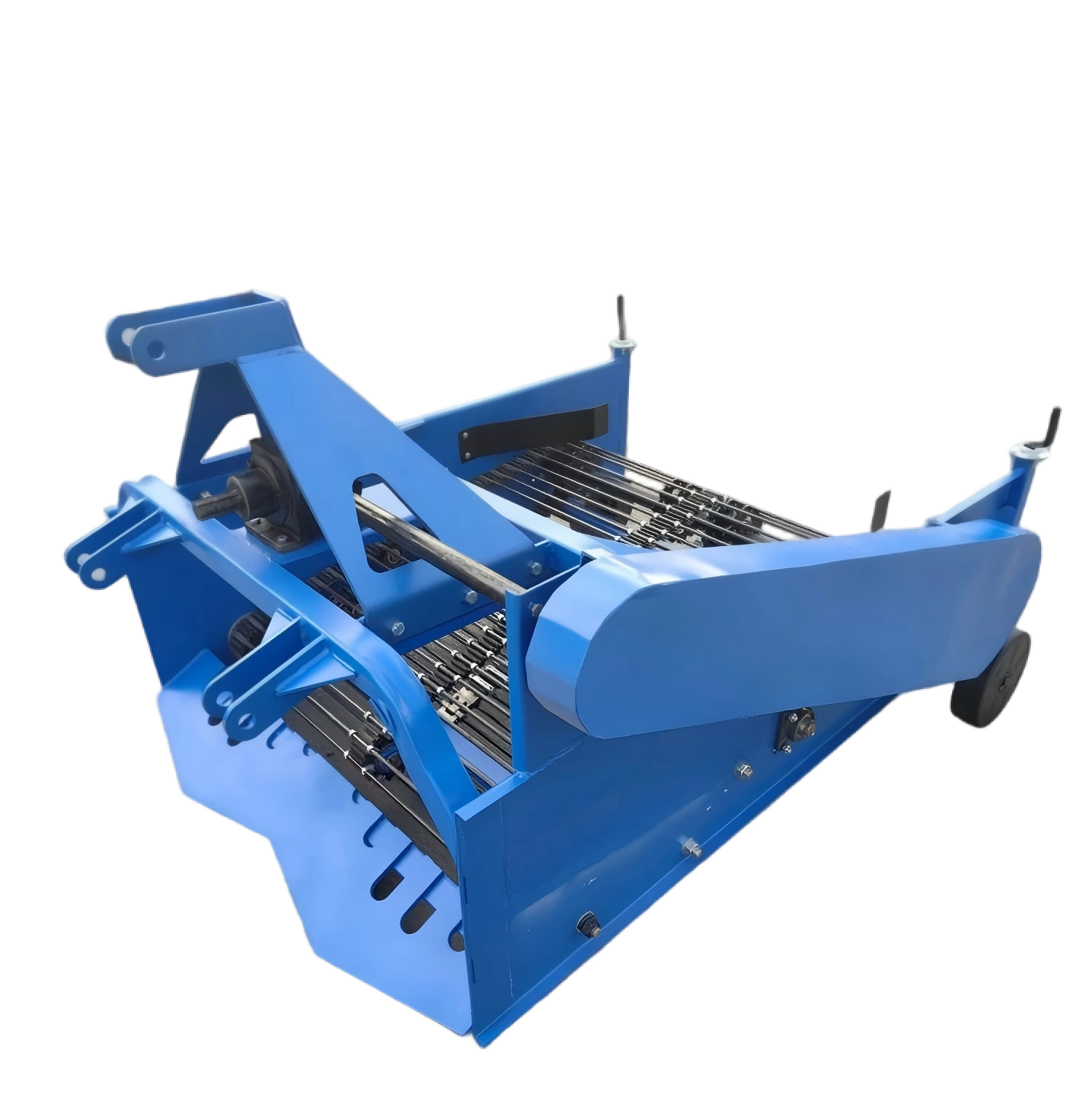

Potato Harvester Tractor Towed Type 4UY Series

Product Information

● Our 4UY Series Potato Harvester is a big step forward for farm harvesting work. It’s built to make traditional farming faster, more reliable and way more efficient.

● This tough, all-in-one machine digs and picks potatoes, sweet potatoes, yams and onions without hurting the crops. It keeps produce in great shape while getting the job done well.

Product parameters

Typical Configurations by Capacity (for Reference)

|

Model |

4UY-60 |

4UY-80 |

4UY-90 |

4UY-100 |

4UY-130 |

4UY-150 |

4UY-160 |

4UY-180 |

|

Working Width (cm) |

60 |

80 |

90 |

100 |

130 |

150 |

160 |

180 |

|

Working Depth (cm) |

15 - 30 (Applies to all models) |

|||||||

|

Productivity (ha/hour) |

0.20-0.33 |

0.27-0.40 |

0.33-0.47 |

0.40-0.53 |

0.47-0.60 |

0.53-0.67 |

0.67-0.80 |

0.67-1.00 |

|

Machine Weight (kg) |

215 |

255 |

275 |

325 |

365 |

405 |

435 |

475 |

|

Required Power (hp) |

20-35 |

25-45 |

30-50 |

35-70 |

50-80 |

55-85 |

60-90 |

90-120 |

|

Potato Recovery Rate (%) |

≥98 (Applies to all models) |

|||||||

|

Potato Skin Damage Rate (%) |

≤2 (Applies to all models) |

|||||||

|

Drive Speed (r/min) |

540 (Applies to all models) |

|||||||

Key Advantages

● Premium Screening System

Our exclusive 65Mn spring steel rod construction with belt-type connection provides exceptional durability and flexibility. The specially designed screening system ensures gentle handling of crops while efficiently removing soil, resulting in less than 2% damage rate. This innovative design extends machine life while maintaining superior harvest quality.

● Advanced Transmission Technology

The harvester-specific gearbox utilizes hardened, wear-resistant gears that withstand heavy-duty operations. Combined with side chain drive featuring tensioner wheels, this system delivers smooth, stable power transmission with minimal energy loss. Compatible with most tractor PTO systems for versatile farm integration.

● Dual Vibration Efficiency

Two independently operating vibration wheels create optimal shaking frequency and amplitude for rapid soil separation. This dual-system approach increases harvesting speed by 30% compared to conventional single-vibration harvesters while ensuring thorough cleaning of crops.

Core Advantages

● Intelligent Depth Control

The rear-mounted adjustable depth wheel allows precise depth setting from 15-30cm based on crop type and soil conditions. This feature, combined with the ridge closer attachment, prevents crop bruising and ensures straight, even harvesting rows for easier collection.

● Multi-Crop Versatility

Engineered to handle various root vegetables including potatoes, sweet potatoes (yams), and onions with simple adjustment. The modular design allows quick conversion between different crop types, making it a cost-effective solution for diversified farms.

● Wide Application scenarios

Commercial potato farms, sweet potato growers, onion producers, diversified vegetable farms, agricultural contractors, and farming cooperatives.

Product application

FAQ

Contact: Ella

Tel: +86 19337183882

E-mail: sif@sifmachinery.com

Address: Gaocun,Guang Wu Road, XingYang, Zhengzhou, HeNan, China