Animal Feed Pellet Making Machine Animal Feed Pellet Mill Line Animal Feed Machine

Product name:animal feed pellet machine

Voltag:220V/380V

Dimension(L*W*H):85*35*91(mm)

Application:Make Animal Feed

Material:Stainless Steel

Electric Power:4kw

Output(Kg/H):Around(50-80)

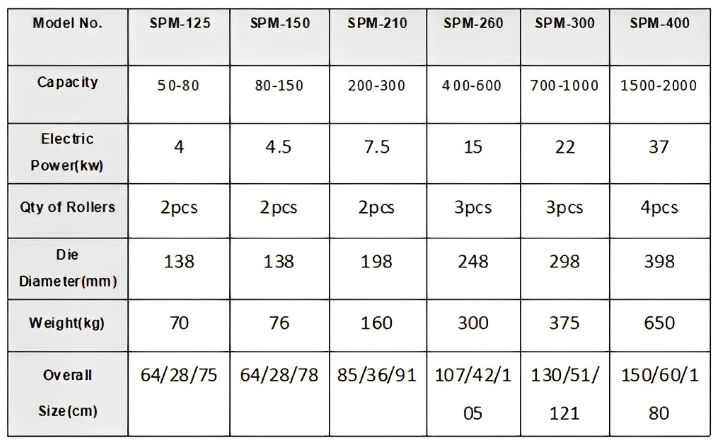

Capacity:50-2000kg/h

Product description

The animal feed pellet machine is made by special technology. The processed feed is dried in and out. The particle size can be adjusted. The surface of the feed particles is smooth and the hardness is moderate. When working, the mixed powdered feed is added into the hopper without heating, adding water, drying. After extrusion, the feed nutritional value and digestibility are improved, and the quality of the feed particles can also be stored for a long time. It is mainly suitable for processing and producing various livestock and poultry and aquatic granular feed for medium and small-scale aquaculture professionals.

Product features

1. The animal feed pellet machine's powder feed and grass meal can be granulated without (or a little) liquid addition. Therefore, the moisture content of pellet feed is basically the moisture content of materials before granulation, which is more conducive to storage.

2. The particles made by this machine are of high hardness, smooth surface and full degree of internal maturation, which can improve the digestion and absorption of nutrients, and can kill the common pathogenic microorganisms and parasites. They are suitable for feeding rabbits, fish, ducks and experimental animals, and can achieve higher economic benefits than mixed powder feed.

3. The animal feed pellet machineis equipped with 2.5mm--12 kinds of aperture molds, which can be used to granulate different materials to achieve the best effect.

4. Adapt to different materials to ensure the pressing effect. Corn bran, soybean meal and other grain concentrate and corn stalk, peanut stalk, clover and other raw materials of coarse fiber can be formed at one time or mixed in different proportions. In similar granulating equipment, the roller part is the central part of the whole equipment, and high-quality alloy steel is adopted to improve the service life of the roller.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Ella

Phone: 008619337183882

E-mail: sif@sifmachinery.com

Whatsapp:0086-19337183882

Add: Gaocun Industrial Zone, Xingyang Zhengzhou, Henan 450000