Soybean Grinding Machine Corn Milling Machine Disc Mill

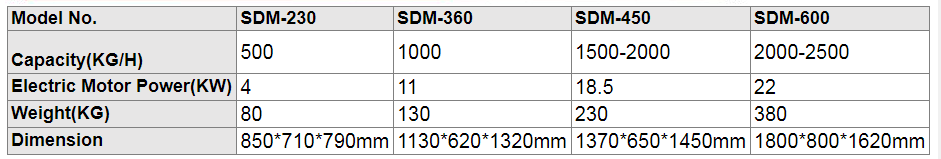

Product name:disc mill machine

Feed types:Self-priming

Capacity:1500-2000 Kg/H

Electric Motor Power:18Kw

Weight:230 Kg

Dimension(L*W*H):1370*650*1450mm

Usage:Milling Grains

Function:Multifunction

Product description

The Grain Grinding Machine can crush granular refined feed such as corn, sorghum, wheat, beans and cakes; It can also be used to pulp and pulverize massive materials such as fresh sweet potato, potato, kudzu root, cassava, etc., or crush forage grass, dry weeds, sweet potato seedlings, peanut seedlings, corn straw, dry grain straw, etc. into coarse fodder; It is an ideal, effective and economical equipment for small and medium-sized pig farms, pig farmers and sideline processors in rural areas. It is also widely used as fine powder and even ultra-fine powder processing in enterprises and institutions such as chemical industry, medicine, dyes, coatings, pesticides, metallurgy, ceramics, food, non-metallic minerals and scientific research.

Product features

1. Inject proper amount of lubricating oil into each oil injection hole to ensure good lubrication during operation;

2. The moving parts shall be filled with grease once a day, and the main bearing shall be filled with lithium-based grease when it is used for 300 hours;

3. When the blade is blunt, it should be sharpened in time. When sharpening, it should be cooled with water to prevent annealing; The moving knife should be sharpened on the inclined surface, and the angle should not be changed. The fixed knife should be sharpened on the upper surface. It is not allowed to sharpen the joint surface of the two blades. The symmetrical two moving knives are not allowed to be used together with the old ones;

4. When the hammer working angle is blunt, open the upper cover, remove the pin at one end of the pin shaft, adjust the working angle, and install it according to the hammer arrangement diagram;

5. Hammer piece, pin shaft, fan blade, etc. cannot be self-made to prevent the whole machine from being damaged by weight loss;

6. In case of abnormal vibration and sound during operation, stop the machine immediately for inspection. If the bearing is damaged, replace the original bearing of the same model in time;

7. Frequently check the hammer piece, pin shaft, pin, fan blade, and replace them in time if they are seriously worn.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Ella

Phone: 008619337183882

E-mail: sif@sifmachinery.com

Whatsapp:0086-19337183882

Add: Gaocun Industrial Zone, Xingyang Zhengzhou, Henan 450000